|

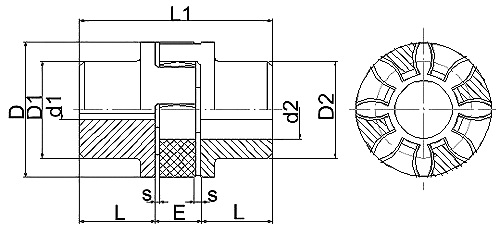

The polyurethane elastomer of the LX (formerly XL) star-shaped elastic coupling is limited by the convex claw block, which avoids the internal deformation caused by the impact and the external deformation caused by the centrifugal force; the large concave surface of the claw makes the involute tooth The surface pressure on the top is small, and the teeth will not wear or deform even if they are overloaded.

Star elastic coupling transmission principle:

1. XL type star-shaped elastic coupling is made of engineering plastics as elastic element. It is suitable for connecting the transmission shaft system of two coaxial lines. It has the compensation of relative offset, cushioning, shock absorption and wear resistance of two axes. .

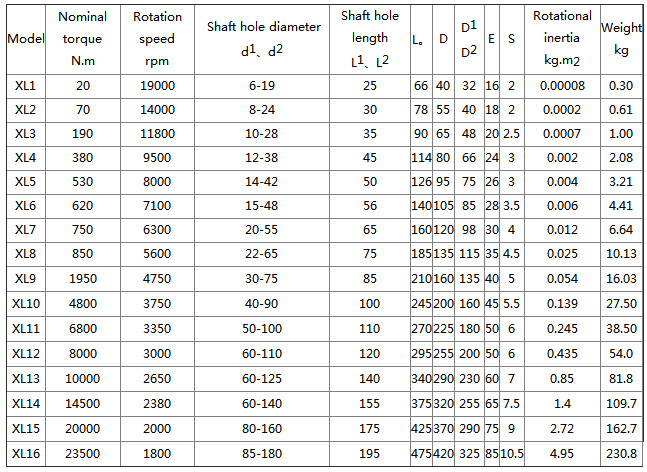

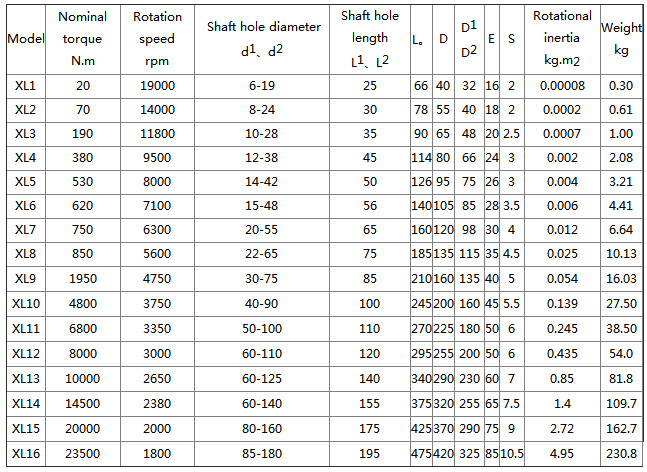

2. The transmission torque is 20-35000.N.M, the working temperature is -35-+80 degrees Celsius and is interchangeable with the German ROTEX coupling.

3. The polyurethane elastomer is limited by the convex claw block to avoid internal deformation due to impact and external deformation caused by centrifugal force.

4. The concave surface of the claws makes the surface pressure on the involute teeth small, and the teeth will not wear or deform even if they are overloaded.

LX (formerly XL) star-type flexible coupling high-speed operation strength:

The LX (formerly XL) star-type flexible coupling will accelerate its wear due to the centrifugal force caused by the centrifugal force at high speed, and the outer casing is added. In addition to being dust-proof and oil-removing, insufficient amount of thinning may cause interference, and excessive thinning may weaken the strength of the teeth and may have a large backlash. The contact condition of the external teeth is improved, which avoids the disadvantages of the stress of the straight tooth end edge extrusion under the angular displacement condition, and improves the friction and wear condition of the tooth surface, reduces the noise, and has a long maintenance period. The outer end of the LX (formerly XL) star-shaped elastic coupling has a horn shape, so it should not be used under high speed and impact load, nor should it be used for vertical shaft connection. When designing the overall structure of the star-shaped flexible coupling, it is necessary to pay full attention to the lubrication and dustproof between the tooth surface and the roller, as well as safety protection. Because the chain breaks, it may cause personal accidents. The radius of curvature of the drum curve is proportional to the amount of thinning of the inner teeth on one side, that is, it is related to the meshing clearance of the teeth, which makes the inner and outer teeth easy to assemble and disassemble.

Elastomer selection for LX (formerly XL) star-type flexible couplings:

1. The polyurethane elastomer of the LX (formerly XL) star-type elastic coupling is limited by the convex claw block to avoid internal deformation due to impact and external deformation caused by centrifugal force.

2. The concave surface of the large claw makes the surface pressure on the involute tooth small, and the tooth will not wear or deform even if it is overloaded.

3, axial plug-in assembly, easy to blindly install, save time.

4, small size, small moment of inertia, maintenance-free.

5, easy to visual inspection. The middle elastomer is made of German-formulated polyurethane and is available in a variety of hardnesses.

|

- gear coupling

- flexible coupling

- cardan shaft

- disc coupling

- jaw coupling

- grid coupling

- tyre coupling

- slider coupling

- chain coupling

- roller coupling

Mobile: 18118917615 (Manager Zhu) 13952897281 (Manager Xu)

Mobile: 18118917615 (Manager Zhu) 13952897281 (Manager Xu)Fax:0511-83993666

E-mail:sales@zjlianxin.cn

Add:No. 6, Middle Road, High-tech Industrial Park, Zhenjiang City, Jiangsu Province

jaw coupling

LX star flexible coupling

Time:18-09-21

jaw coupling

LX star flexible coupling

Time:18-09-21

|

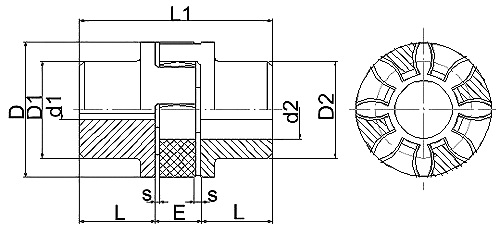

The polyurethane elastomer of the LX (formerly XL) star-shaped elastic coupling is limited by the convex claw block, which avoids the internal deformation caused by the impact and the external deformation caused by the centrifugal force; the large concave surface of the claw makes the involute tooth The surface pressure on the top is small, and the teeth will not wear or deform even if they are overloaded.

Star elastic coupling transmission principle:

1. XL type star-shaped elastic coupling is made of engineering plastics as elastic element. It is suitable for connecting the transmission shaft system of two coaxial lines. It has the compensation of relative offset, cushioning, shock absorption and wear resistance of two axes. .

2. The transmission torque is 20-35000.N.M, the working temperature is -35-+80 degrees Celsius and is interchangeable with the German ROTEX coupling.

3. The polyurethane elastomer is limited by the convex claw block to avoid internal deformation due to impact and external deformation caused by centrifugal force.

4. The concave surface of the claws makes the surface pressure on the involute teeth small, and the teeth will not wear or deform even if they are overloaded.

LX (formerly XL) star-type flexible coupling high-speed operation strength:

The LX (formerly XL) star-type flexible coupling will accelerate its wear due to the centrifugal force caused by the centrifugal force at high speed, and the outer casing is added. In addition to being dust-proof and oil-removing, insufficient amount of thinning may cause interference, and excessive thinning may weaken the strength of the teeth and may have a large backlash. The contact condition of the external teeth is improved, which avoids the disadvantages of the stress of the straight tooth end edge extrusion under the angular displacement condition, and improves the friction and wear condition of the tooth surface, reduces the noise, and has a long maintenance period. The outer end of the LX (formerly XL) star-shaped elastic coupling has a horn shape, so it should not be used under high speed and impact load, nor should it be used for vertical shaft connection. When designing the overall structure of the star-shaped flexible coupling, it is necessary to pay full attention to the lubrication and dustproof between the tooth surface and the roller, as well as safety protection. Because the chain breaks, it may cause personal accidents. The radius of curvature of the drum curve is proportional to the amount of thinning of the inner teeth on one side, that is, it is related to the meshing clearance of the teeth, which makes the inner and outer teeth easy to assemble and disassemble.

Elastomer selection for LX (formerly XL) star-type flexible couplings:

1. The polyurethane elastomer of the LX (formerly XL) star-type elastic coupling is limited by the convex claw block to avoid internal deformation due to impact and external deformation caused by centrifugal force.

2. The concave surface of the large claw makes the surface pressure on the involute tooth small, and the tooth will not wear or deform even if it is overloaded.

3, axial plug-in assembly, easy to blindly install, save time.

4, small size, small moment of inertia, maintenance-free.

5, easy to visual inspection. The middle elastomer is made of German-formulated polyurethane and is available in a variety of hardnesses.

|

Copyright © Zhenjiang Lianxin Heavy Industry Machinery Co., Ltd. All Rights Reserved . Technical Support:Erun

Add:No. 6, Middle Road, High-tech Industrial Park, Zhenjiang City, Jiangsu Province Tell:0511-83998589